Calibration OVERVIEW

Overview

In the world of metrology and calibration, labs deal with daily challenges that require a careful touch. Navigating these challenges for better compliance and efficiency has become more complicated.

Quality standards have evolved, posing challenges for calibration labs. What used to be a straightforward requirement of traceability has now become a dance with accrediting bodies, strict quality programs, regulatory agencies, and auditors in the metrology community. This ever-changing environment emphasizes the need to adapt and approach precision and compliance in a more refined way.

In this challenging setting, labs aren't just trying to meet standards; they're leading the way, going beyond mere compliance. The goal is not just to be accurate and follow regulations but to set new standards in the dynamic world of metrology and calibration

Downloads

Calibration Metrology Labs – Key Challenges!

- Diverse Expectations: Balancing varied expectations from clients, management, administration, technicians, quality, and engineering.

- Process Complexity: Addressing a range of disciplines and ensuring that lab processes effectively meet the needs of different stakeholders

- Data Management: Effectively collecting, storing, and analyzing calibration data for historical parametric analysis and practical measurement uncertainty evaluation.

- Automation Transition: Overcoming the challenges associated with transitioning from traditional paper, manual, and semi-automated tasks to automated processes, especially for routine calibration of complex instruments.

- Corporate Demands: Meeting corporate demands for increased productivity and higher profits while maintaining quality standards and operational efficiency.

- Technological Advancements: Keeping pace with rapid technological advancements in calibration and metrology to stay competitive and relevant.

- Skill Development: Ensuring that calibration technicians and staff possess the necessary skills to operate advanced equipment and implement new technologies.

- Resource Optimization: Optimizing resources, including time, personnel, and equipment, to achieve efficiency without compromising on precision and accuracy.

- Continuous Improvement: Implementing a culture of continuous improvement to address emerging challenges and stay adaptable in a dynamic industry landscape.

Introducing Labsols Calibration & Metrology Lims,, Your Solution to Operational Excellence.

A Great Tool - Complete Solution For Managing Calibration & Metrology Laboratory Business Process

- Manage Calibration Process and Operation flow

- Manage Sales Process (Sales Order to Shipment to Billing)

- Manage Lab Standards/Master Products

- Manage Lab Staff workload and lab performance

- Manage Calibration documents and communication

- Manage Lab Customers and connected to them all time

- Manage Certificates - Just reading and generate certificate

Labsols revolutionizes the calibration industry with 'CALIBRATION LIMS' —a software solution incorporating intelligent calibration management, a customer portal, and a mobile extension. This tool automates traditional tasks, streamlining routine calibration and maintenance workflows for instruments of varying complexity.

CALIBRATION LIMS captures the entire calibration lab process, simplifying it into seven traceable processes, while automating reporting, documentation, issue logging, and communication. This reduces administrative overhead, ensuring data integrity and confidence in properly calibrated instrumentation." Look for yourself

Comes with Powerful Analytics,

Mobile Apps & Business Intelligence

- Experience a customized Lab Mobile App designed to meet the unique needs of calibration labs. Track samples effortlessly, receive instant Alerts and Advance push notifications, Download reports on-the-go, and access a KPI dashboard for comprehensive insights and Offline Connectivity. Labsols ensures seamless integration with CALIBRATION LIMS, bringing efficiency to your calibration processes.

- Labsols BI revolutionizes data intelligence for calibration labs, enhancing operational efficiency. This innovative solution integrates data from diverse sources, including testing equipment and CALIBRATION LIMS. Real-time monitoring of key performance indicators (KPIs) such as testing volumes, turnaround times, and resource utilization is at your fingertips. For calibration labs embracing cloud-based capabilities, Labsols BI harnesses the power of AI/ML and advanced analytics for lab-wide asset monitoring and business intelligence. Unlock the full potential of a smart, connected calibration lab with Labsols BI.

Labsols Lab Add-On Tools & Integration Capabilities

A Great Tool - Complete Solution For Managing Calibration & Metrology Laboratory Business Process

- LIMS Integration with Accounting Systems (Sage/Xero/QuickBooks, etc)

- LIMS Integration with Devices & Instruments (Via Folder/API, etc)

- LIMS Integration with Document Management System (MFiles, etc)

- LIMS Integration with Barcode for Labeling

- LIMS Integration with CRM and Support Systems

- LIMS Integration with Third Party Systems

- Migration of Existing Data - various types

- Lab BI (Business Intelligence) Tool with AI & ML

- Lab Customer Portal - For lab's external customers

- Lab Customer Mobile Apps - Get information on the move

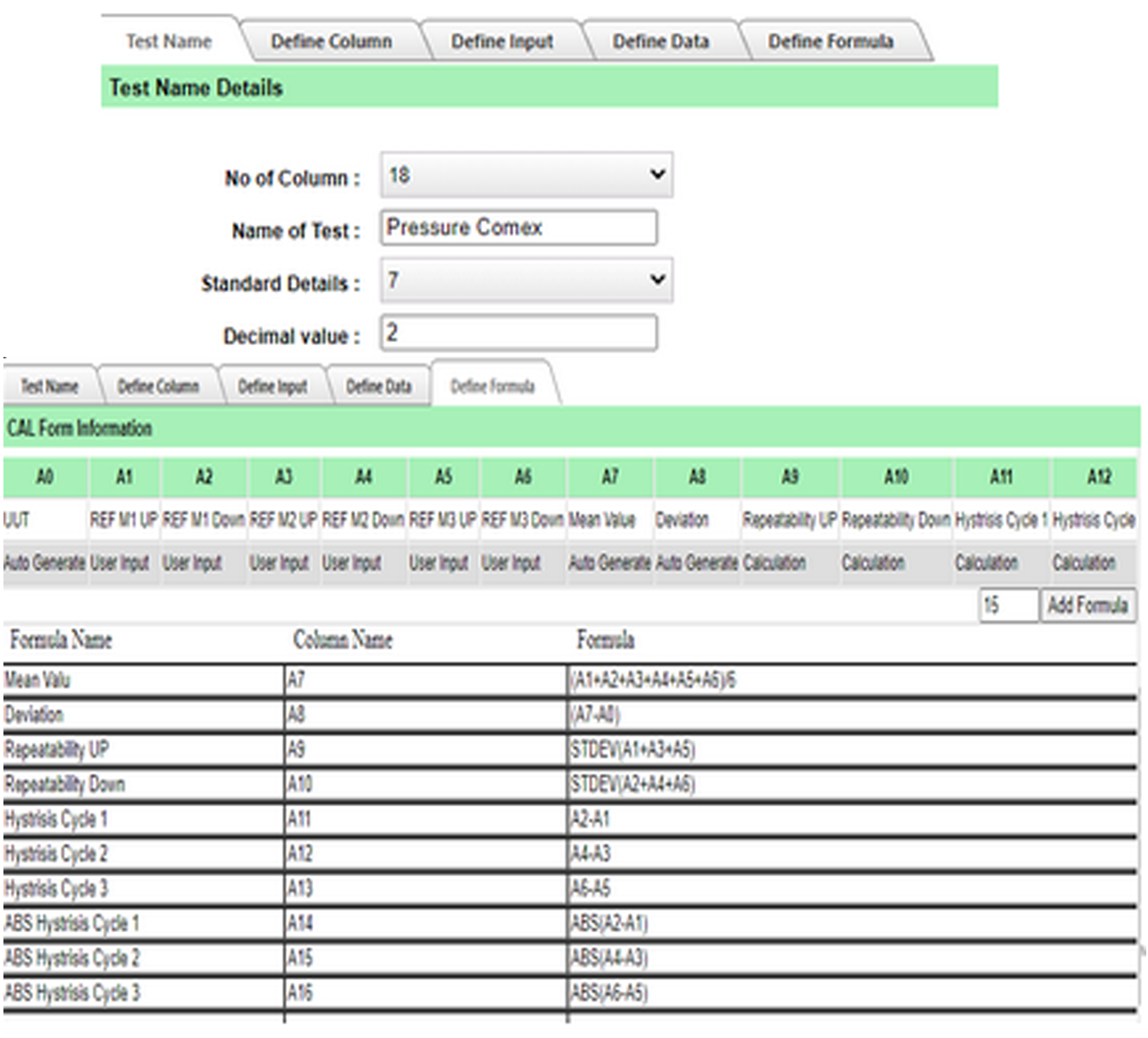

Configuring Uncertainty

Uncertainty Calculation - The dynamic uncertainty setup screen allows the user to create new rules and calculations to set new uncertainty and edit existing ones. Automate uncertainties & corrections. It allows users to configure uncertainty for Thermal Calibration, Mechanical Calibration Services, and Dimensional Metrology Calibration. Electro Technical Calibration, Pressure Calibration, Analytical Calibration etc. Support Type A and Type B measurement uncertainties.

In the Setup module's Uncertainty menu, your lab team can easily manage and configure uncertainty parameters for accurate results.

Name : Define name of the uncertainty. Here you can create structure for a uncertainty configuration by defining 'no of column'; 'standard value' and decimal value.

Column Name : Define column name of calculation table. Whatever column name you define it will show same name in the certificate

Define Input : Here user can define input type of each column- like predefined field (like master value), user input (like reading of equipment) and calculation fields.

Define data : Here you can define maximum no of row needed for the uncertainty Define Formula: Here you can define row wise and column wise calculation formulas.

(+44) 118 328 2490

(+44) 118 328 2490

(+91) 9123329271

(+91) 9123329271